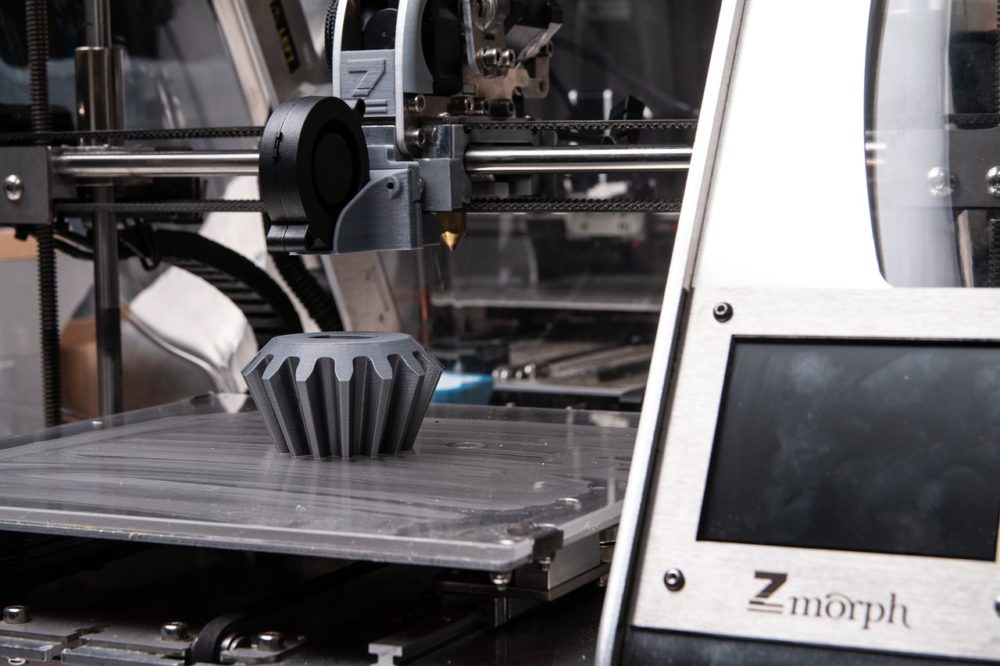

3D printing has moved from a hobbyist’s finest good friend to one of the vital helpful instruments in practically each business. With a pc and a bit of warmth, you may flip strings of plastic filament into practically something. Extra superior kinds of 3D printers may even lay down layers of metallic, glass, or cement. There may be even a 3D printer in orbit above the Earth on the Worldwide Area Station. What are the advantages of 3D printing in house and can we see extra of it sooner or later?

Preserving Rocket Weight Low

That very same gravity that retains you from floating away from the Earth’s floor additionally makes it tough for us to get into outer house. You could transfer at greater than 40,000 kilometers per hour to succeed in what’s referred to as escape velocity and break freed from the Earth’s gravitational pull. The extra your rocket weighs, the harder it’s to succeed in escape velocity, so aerospace engineers are all the time in search of new methods to cut back the quantity of weight we’re launching into orbit.

3D printing provides astronauts all the things they should make a large number of completely different objects, all with no need to ship every bit into orbit. In the event that they want a bowl, they will print a bowl, and all NASA has to do is ship up a few rolls of 3D printing filament.

Forgot Your Instruments?

In case you overlook your instruments at residence, you may often simply drive again and decide them up. What do you do for those who’re an astronaut and house is 254 miles under your ft? You print a brand new one! Astronauts on the Worldwide Area Station have labored with engineers and designers on the bottom to print specialised instruments that they didn’t deliver with them. In 2014, astronauts printed a wrench that they wanted to hold out a restore.

Not like printing right here on Earth, the wrench wanted to have transferring components however needed to be fully enclosed to forestall the small items from floating away within the station’s microgravity. It took 4 hours to print and when it was carried out, the astronauts might end the job they’d began.

Constructing Spacecraft

We’ve been constructing spacecraft for many years, and as we’ve discovered we’ve modified our manufacturing methods. What began with hand-crafted items modified to meeting traces and robotic manufacturing. 3D printing isn’t a brand new idea both although when it debuted in 1986 it didn’t look very like the know-how we all know at this time. Quickly, we could even see starships product of absolutely 3D printed components, particularly if we begin designing them with items which can be too advanced to manufacture historically.

If we begin constructing large ships in house that aren’t designed for atmospheric flight, like lots of people who we see in science fiction films and tales, microgravity 3D printing might make a large distinction — it’s lots simpler to ship a robotic printer out into the vacuum of house than it’s to ship a human astronaut in a spacesuit.

Recycling in Area

One drawback with sending humanity into outer house is that we are likely to generate trash wherever we go. The Worldwide Area Station isn’t any exception. 3D printing provides astronauts a option to flip their plastic waste into one thing helpful by recycling it into 3D printing filament. There are presently two 3D printers on the Worldwide Area Station — the Refabricator and an Additive Manufacturing Facility (AMF). One other system, referred to as The Recycler, works by turning plastic waste into 3D filament that they will feed again into the Refabricator.

Which means there may be much less waste that must be discarded or returned to Earth, preserving issues cleaner for everybody.

Printing…Meat?

Preserving astronauts fed and wholesome may be difficult, particularly in the course of the form of long-distance journeys we hope to undertake sooner or later. In Star Trek, they solved that drawback with the invention of replicators — units that would materialize practically any meals or drink you can think about with nothing greater than a voice command. Whereas we haven’t fairly discovered tips on how to replicate meals, 3D printing would possibly make it a bit bit simpler.

Sooner or later, 3D printers might be able to print anything from food to medicine and something in between, utilizing a restricted retailer of base supplies. Whereas a 3D printed steak may not sound appetizing when you may simply drive to the grocery retailer and purchase one, for those who’re a couple of million miles from the closest cow, it could be the tastiest meal you can cook dinner up.

In-Flight Repairs

The very last thing you need to deal with in outer house is a breach in your hull. Exterior injury is hard to repair, even on Earth, and also you don’t need to spend astronauts out until you completely need to. Why not use a 3D printer on the top of a robotic arm to have an effect on repairs if one thing goes incorrect or punches via your hull?

The deep-space ship Aether featured within the current Netflix film The Midnight Sky showcased this potential software for the know-how. After the ship flies via an ice storm, the crew is ready to ship bots out alongside rails affixed to the outside of the craft to repair the injury. It’s a singular have a look at 3D printing know-how that will see extra sensible functions sooner or later.

Wanting Towards the Future

We’re not fairly as much as exploring the galaxy — no less than not but. After we transfer past the Moon and Mars and ultimately our residence photo voltaic system, 3D printing and it’s technological descendents will likely be there to assist us construct all of the items we have to attain our vacation spot safely.