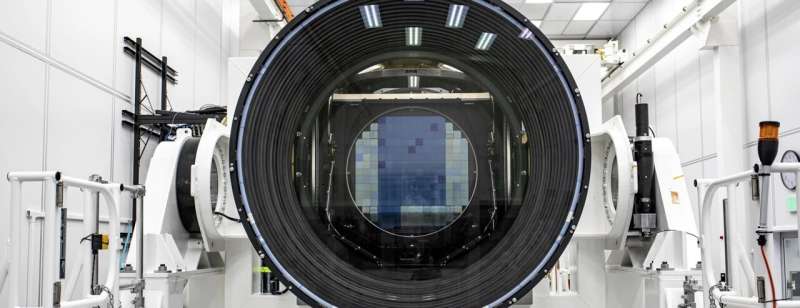

Constructing the world’s largest digital digicam ever made for astronomy, the Vera C. Rubin Observatory’s Legacy Survey of Area and Time Digicam, isn’t any easy activity—that a lot is apparent.

The digicam incorporates a 3,200 megapixel sensor array, a few of the largest lenses ever constructed, and sophisticated electronics meant to take an ocean of astrophysical information off the digicam and ship it out into the world.

What could also be much less apparent is how a lot work goes into ensuring the digicam, constructed on the Division of Power’s SLAC Nationwide Accelerator Laboratory, works. The system was, in spite of everything, customized to see wider and deeper into our universe than any digicam has earlier than. And, within the course of, drive the hassle to grasp darkish matter and darkish vitality. Turning such formidable plans and designs into realities goes to return with some trial and error and a complete lot of calibration and testing.

Right here, three members of the group chargeable for all that calibration and testing discuss what’s gone into making the LSST Digicam the most effective it may be.

Making gorgeous photos even higher

One of many central challenges, says LSST Digicam scientist Yousuke Utsumi, is “changing photos to scientific data.” In spite of everything, the digicam just isn’t designed simply to take fairly footage, however quite to create a exact map of the universe, and that requires taking detailed, correct photos of distant galaxies. “We wish to measure galaxies exactly to grasp the character of darkish matter.”

Doing so requires extra than simply specifically designed lenses and sensors, Utsumi says, as a result of irrespective of how effectively designed and constructed these elements are, there will likely be imperfections. As an illustration, take into account a picture taken by an odd digicam: There’ll all the time be some distortions in form and shade close to the sides. There may also be slight distortions within the digital sensors as effectively, and related results will maintain true for the LSST Digicam. “We have to perceive what is going on on there so we are able to right for it.”

Utsumi and his group took hundreds of photos over three months with the LSST Digicam sensors of all types of shapes and patterns. They then in contrast the digicam’s photos with the originals to grasp the way to right for any distortions or errors. The group has additionally labored on the way to right different points, similar to the truth that brighter objects seem bigger than they really are, in addition to “ghosts,” or photos of an object that seem due to digital crosstalk between sensors throughout the digicam.

“We all know quite a bit in regards to the digicam now, so will probably be thrilling to see the way it works on the telescope,” Utsumi says.

Constructing a extra foolproof digicam

Though Utsumi’s work is central to creating the digicam work as greatest as it could, the sensors and lenses are solely two units of elements in a digicam the scale of a small SUV. The digicam has a refrigeration and vacuum system, a number of on-board computer systems and an array of different electronics that monitor and management the digicam’s operation.

Stuart Marshall, the LSST Digicam’s operations physicist, is answerable for ensuring all of these programs perform correctly. “As soon as the whole lot is working appropriately, we are able to sit there taking information, and there is a small military of individuals to have a look at what comes out and do science,” he says. “I’ve targeting ensuring that the whole lot works to make that occur.”

Getting there means quite a lot of behind-the-scenes work on the digicam infrastructure. “Should you work backward from the sensors, for them to work, they must be chilly. They must be at minus 100 levels Celsius, or -148 levels Fahrenheit, and you’ll’t be at minus 100 levels except you are in a vacuum, and we now have to have energy and communication and the info has to stream.”

At this level, which means quite a lot of testing and, in case one thing is flawed, attempting out completely different concepts to establish the reason for an issue and discover a resolution. As an illustration, Marshall says, he is spent quite a lot of time within the final 12 months updating the vacuum system to enhance its reliability. In consequence, the digicam group has modified some valves and up to date software program to make the system extra foolproof. “Should you’re on prime of a mountain at 9,000 toes in the midst of the telescope dome, it is simpler to make a mistake ,” since there’s much less oxygen at altitude and extra issues shifting round in comparison with the clear room at SLAC, Marshall says. “So we’re attempting to verify the system can catch errors earlier than any injury is completed. There’s an terrible lot of that constructed into the entire digicam system.”

Getting ready digicam controls for crunch time

A maybe subtler problem, says senior scientist Tony Johnson, is ensuring all of the digicam software program is working in addition to it could. Johnson works on the digicam management software program, which turns it on and off, reacts to irregular circumstances, adjusts digicam parameters as wanted and shuts it down if one thing goes notably flawed. He additionally works with the info acquisition system, which takes information off the digicam sensors and sends it out into the world.

“At this stage, the whole lot is usually completed, however myriad issues may be improved,” Johnson says. “As an illustration, can we reliably write a picture from the info acquisition system inside two seconds each single time, or does it typically take a bit longer, and typically that causes an issue?”

So, Johnson says, he and his group work to trace down points like these, which can contain software program or {hardware}, and ensure all of the items work collectively as anticipated.

One other challenge Johnson works on: Ensuring the digicam will work as anticipated as soon as it is made the journey to Chile, the place it’ll sit atop the Simonyi Survey Telescope at Rubin Observatory and start its work.

“One side of that is the digicam has been constructed by a reasonably small group of individuals, and there are a reasonably small group of people who find themselves knowledgeable in every a part of the digicam,” Johnson says. “What we have to transition to the specialists who will function the observatory day and evening, so we now have to do a good quantity of data switch.” Partly that is a matter of documentation, however it additionally means working with the scientists in Chile to establish potential issues, proceed to enhance software program, and usually make the system extra dependable.

“It is a problem, however more often than not it is an thrilling problem,” Johnson says. “I feel most of us who’re constructing the digicam should not simply constructing it as a result of we like constructing {hardware} or we like constructing software program, though we might do these issues. We’re constructing it as a result of we see the tip aim of getting new science out of it.”

Quotation:

Testing, testing, testing: How researchers be sure that the LSST Digicam is the most effective it may be (2023, September 29)

retrieved 29 September 2023

from

This doc is topic to copyright. Aside from any truthful dealing for the aim of personal examine or analysis, no

half could also be reproduced with out the written permission. The content material is supplied for data functions solely.